Fristam Pumps

Fristam Pumps places a strong emphasis on hygienic design, making their pumps suitable for applications where cleanliness and product integrity are critical, such as in food processing, dairy production, and pharmaceutical manufacturing.

Innovative Hygienic Pump Solutions for Food, Beverage, and Pharmaceutical Industries

Fristam Pumps specializes in manufacturing high-quality pumps and equipment for various industries, particularly in the food, beverage, and pharmaceutical sectors. They are known for their innovative designs, reliable performance, and hygienic standards.

Fristam Pumps offers a wide range of pump solutions, including centrifugal pumps, positive displacement pumps, and shear pumps. These pumps are designed to handle different types of fluids, such as liquids, viscous materials, and delicate or shear-sensitive products.

In addition to pumps, Fristam also manufactures other equipment, such as mixers, blenders, and homogenizers, which are used in various processing applications.

Fristam Pumps has a global presence and serves customers in many countries around the world. They have a strong reputation for providing reliable and efficient pumping solutions, backed by excellent customer service and technical support.

Connect with a Triangle team member to learn more!

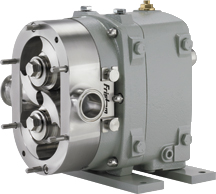

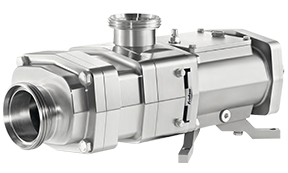

Fristam Positive Displacement Pumps:

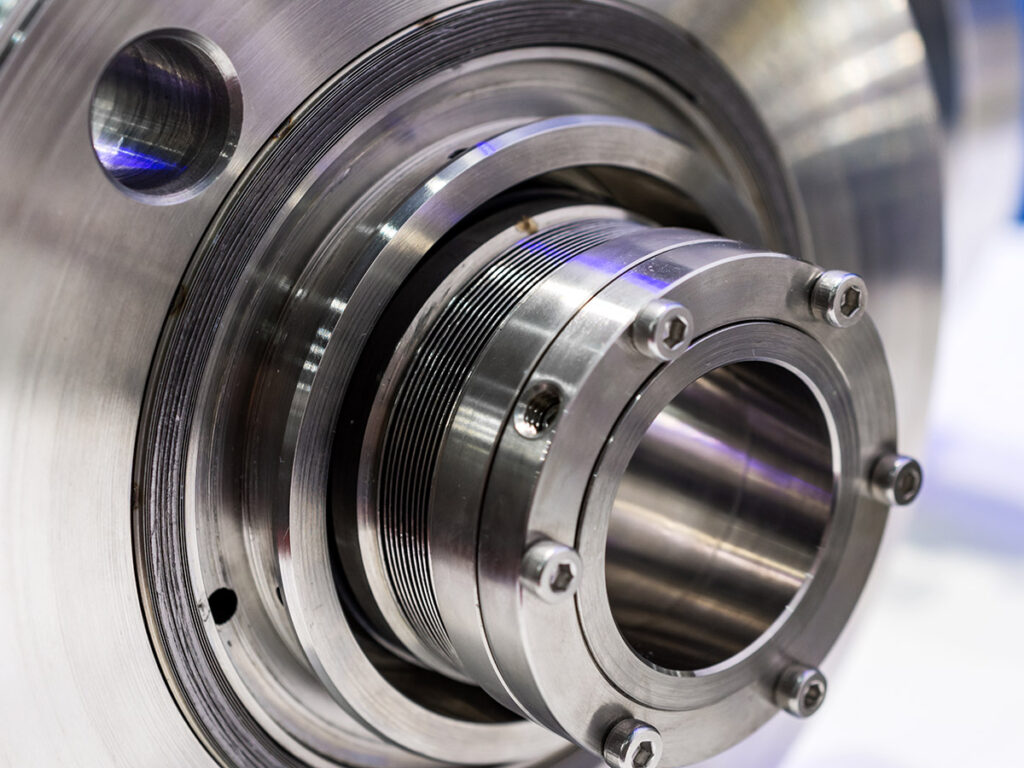

Fristam combines precision machining and innovative design to build sanitary positive displacement pumps that deliver gentle performance and a long service life. With circumferential piston, rotary lobe and helical rotary lobe PD pump options available, Fristam pumps streamline clean-in-place procedures and minimize maintenance.

FKL Positive Displacement Pump

FL2 Positive Displacement Pump

FL3 Positive Displacement Pump

Fristam FDS Double Screw Pump

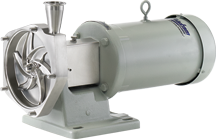

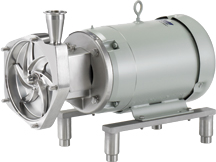

Fristam Centrifugal Pumps:

Designed to provide a long service life, Fristam sanitary centrifugal pumps are constructed of heavy stainless steel materials and feature a unique internal seal engineered to provide years of performance. From standard duty to heavy duty, Fristam offers centrifugal pumps that drive production while streamlining energy costs, CIP processes and maintenance.

FPR Centrifugal Pump

FP Centrifugal Pump

FPX Centrifugal Pump

FZX Sanitary Liquid-Ring Pump

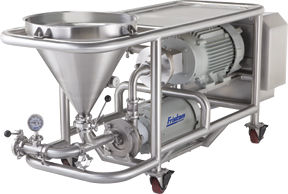

Fristam Mixing Equipment:

Fristam’s line of sanitary mixing equipment includes industrial mixers and blenders for powder induction, in-line blending and complete wet/dry blending. Mixers and blenders from Fristam improve product texture while reducing processing time. Engineered to minimize maintenance, Fristam’s sanitary mixing equipment is designed with continuous duty and efficient CIP processes in mind.

FS Shear Blender

FSI Shear Pump

Fristam Powder Mixer

Fristam Powder Mixer Pilot

The Importance of Optimizing Sanitary Pump Performance for Product Quality and Safety

Sanitary pumps play a critical role in ensuring the quality and safety of food, pharmaceuticals, and other products. But did you know that optimizing the performance of these pumps is just as important as selecting the right pump for the job? In this blog post, we’ll explore why optimizing sanitary pump performance is crucial for maintaining product quality and safety, and provide tips on how to do it effectively.

Speak With A Dedicated Process Equipment Representative

Triangle Process Equipment has developed an extensive product offering through partnerships with industry leading sanitary process manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.